Fabrication Services

POW’s fabrication team can help you bring your ideas to life. We specialise in laser cutting, CNC machining & custom project & furniture builds.

LASER CUTTING

POW’s fabrication team can help you bring your ideas to life. We specialise in laser cutting, CNC machining & custom project & furniture builds.

Regular (5 to 7 day turnaround):

$2.50/minute with a $50 minimum*

Rush (less than 5 days):

$3.75/minute with a $75 minimum*

Same Day:**

$5/minute with an $100 minimum*

Approximate Cutting Time based on materials

Thin things (ie. paper): 50 inches per minute

3mm acrylic or baltic birch plywood: 30 inches per minute

6mm acrylic or baltic birch plywood: 15 inches per minute

*Additional charges may apply for design, file prep, and processing.

**Subject to availability

RATES

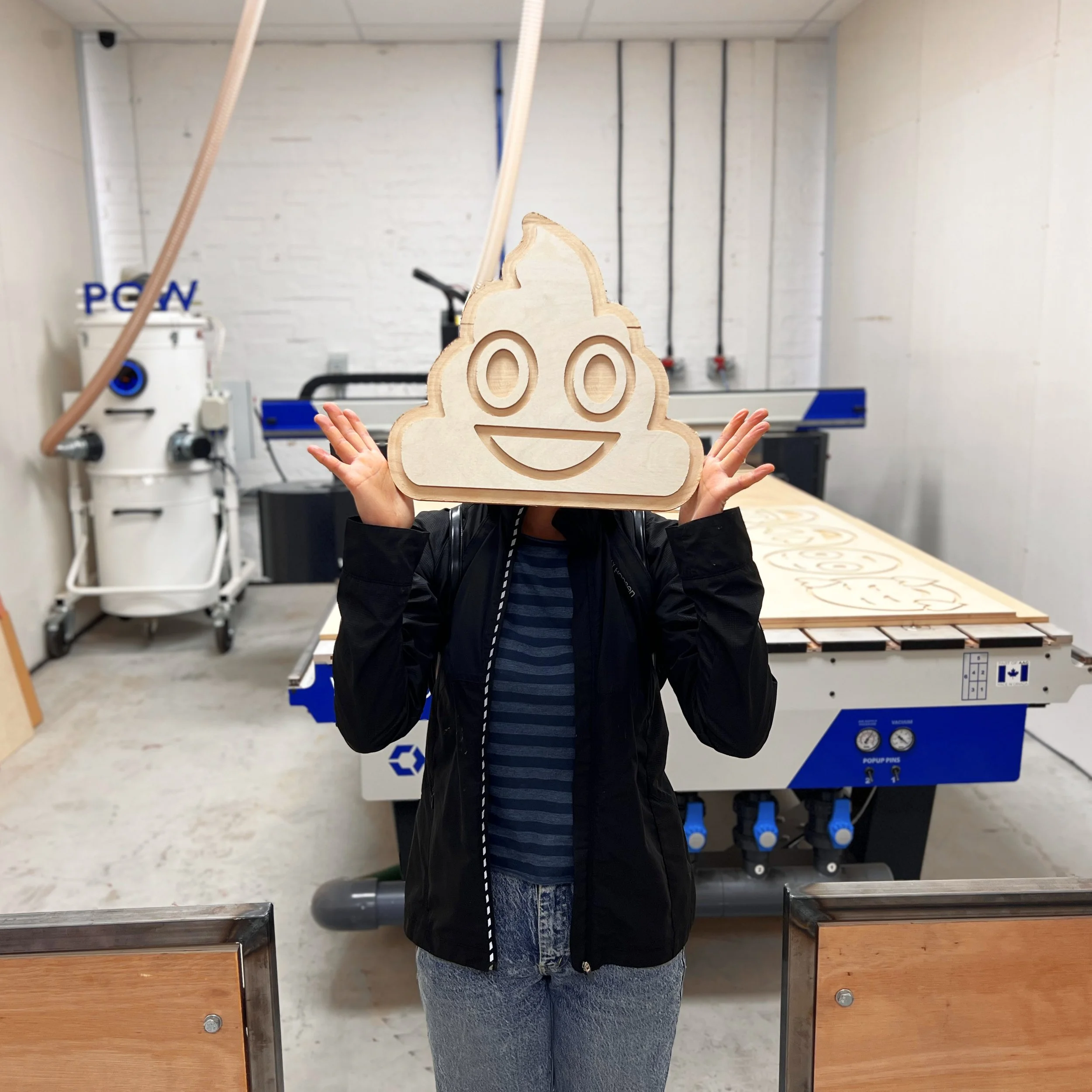

CNC MachininG

Our CNC routers can cut MDF, plywood, hardwood, plastics, and aluminium up to 4'x8'. It's great for furniture, signs, and anything that has a 2D profile.

Regular (1 to 2 week turnaround):

$3.00/min with a $150 minimum*

Rush (less than 1 week):

$4.50/min with a $225 minimum*

Same Day:**

$6.00/min with a $300 minimum*

Removing Tabs $1 per tab

*Additional charges may apply for design, file prep, and processing.

**Subject to availability

RATES

CUSTOM FABRICATION & PROJECTS

We make and manage commissions for individuals, public bodies, offices, architects, designers, and everyone in between.

Design Work

File Setup

Woodworking

Finishing & Oiling

SERVICES

FREQUENTLY ASKED QUESTIONS

-

File Format Requirements

Accepted formats: DXF, DWG, AI, PDF, or SVG

Version compatibility: DXF/DWG saved in 2014 or earlier format

Single file submission: All cut lines in one file (avoid multiple files for one project)

Design Specifications

Units clearly defined: Specify mm or inches in filename or notes

Scale verification: File is drawn at 1:1 scale (actual size)

Line weights:

Cut lines: 0.25mm or thinner

Etch/engrave lines: Clearly differentiated from cut lines

Colour coding:

Engraving: Black

Cutting: Red

Tracing/scoring: Blue

Layer organisation: Different operations on separate layers if applicable

Geometry Requirements

Closed paths: All cut lines form complete, closed shapes

No overlapping lines: Remove duplicate or overlapping vectors

Minimum feature size:

Details ≥ 1mm for wood/plastic

Details ≥ 0.5mm for thin materials

Minimum spacing: 2mm between cut lines minimum

No tiny segments: Avoid line segments shorter than 0.1mm

Technical Considerations

Material specification: Clearly state material type and thickness

Quantity specified: How many pieces needed

Kerf compensation: Indicate if kerf adjustment is required

Grain direction: Specify for wood projects (if critical)

File Preparation

Text converted: All text converted to outlines/curves

Grouped objects ungrouped: Ungroup all elements

Effects removed: No filters, effects, or bitmap elements

Clean file: Remove construction lines, dimensions, and notes from cut file

-

File Format Requirements

3D files: STEP, IGES, or native CAD files (SolidWorks, Fusion 360, etc.)

2D files: DXF, DWG (for profile cutting only)

Toolpath files: Only if specifically requested - G-code in standard format

Design Specifications

Units clearly defined: Model created in mm or inches (specify which)

Origin placement: Set origin at logical reference point

Scale verification: Model is actual size (1:1 scale)

Orientation: Part oriented for optimal machining direction

Geometry Requirements

Minimum radius: Internal corners ≥ 1.5mm radius (3mm+ preferred)

Draft angles: 1-2° draft on vertical walls where possible

Feature accessibility: All features accessible with standard end mills

Undercuts avoided: No overhanging features requiring special tooling

Technical Specifications

Material specified: Type of wood and exact thickness

Tolerance requirements: Critical dimensions and tolerances noted

Surface finish: Specify required surface quality

Quantities: Number of pieces needed

Machining Considerations

Minimum wall thickness: ≥ 3mm for structural integrity

Deep pocket limitations: Depth-to-width ratio considerations

Grain orientation: Critical for strength (specify if important)

Fixture planning: Consider how part will be held during machining

Documentation

Assembly drawings: If multiple parts, show how they fit together

Critical dimensions: Highlight most important measurements

Special instructions: Note any specific requirements or concerns

Reference edges: Indicate which edges are most critical for accuracy

-

Yes, we can help you source materials

-

We will send you an online invoice prior to starting your job, and require payment in full in advance.